Which floor classification does your facility has?

An industrial floor needs to have an appropriate flatness in order to provide a suitable surface for the operation of materials handling equipment (MHE), and an appropriate levelness to ensure that the building as a whole, with all its static equipment and MHE can function satisfactorily.

Floor flatness has a significant impact on the efficiency, performance and safety of materials handling equipment especially fork lift trucks.

Why Flatness is important –

- Operations are more efficient if lift trucks operate at Maximum speed.

- Poor surface regularity will cause excessive vibration on a lift truck and increase down time and maintenance.

- Reduced damage to stock

| Floor classification |

Location and floor use | Maximum permissible limits | |||

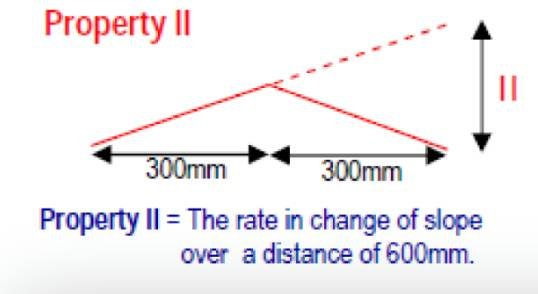

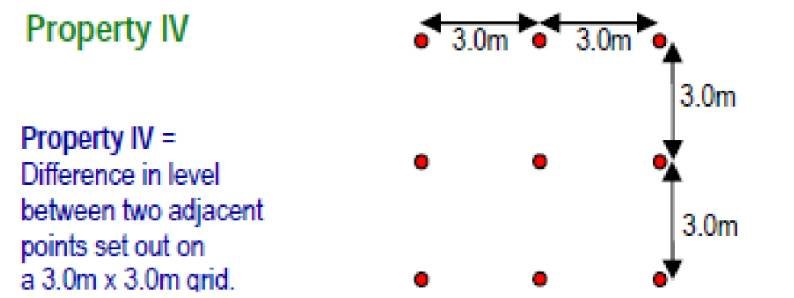

| Property II | Property IV | ||||

| Confidence limits | 95% | 100% | 95% | 100% | |

| FM 1 | Areas of free movement where very strict flatness & levelness may be required | 2.5mm | 4.0mm | 4.5mm | 7.0mm |

| FM 2 |

|

3.5mm | 5.5mm | 8.0mm | 12mm |

| FM 3 |

|

5.0mm | 7.5mm | 10mm | 15mm |

|

|

||||

How to check compliance?

It’s with DIN meter

Please let us know if that helps